Photo Diary: The "Maggie Muggs" Low-Speed

Ramjet Prototype - PART III - TEST FIRINGS

by Larry Cottrill, Editor, jetZILLA Online Magazine

- All photos this page Copyright 2003 Larry Cottrill -

Table of Contents [Construction Sections I-IV go back to Page 1]:

I. The parts lineup [28 August 2003]

II. The tubular truss engine mounts [28 August 2003]

III. Building the diffuser section [04 September 2003]

IV. Bonding the diffuser/flameholder subassembly to

the combustion chamber/nozzle shell [12 September 2003]

Table of Contents [Construction Sections V-VIII go back to Page 2]:

V. Final major assembly steps [22 September 2003]

VI. Details, details [22 September 2003]

VII. Fuel and ignition system work [29 September 2003]

VIII. Finishing up [03 October 2003]

Table of Contents [Maggie Muggs Test Firing Page]:

I. Ben Koopman's Maggie Muggs Clone [April 2005]

II. Maggie Muggs Testing Plan, Hints and Tips

I. Ben Koopman's Maggie Muggs Clone [April 2005]:

Previous section Next section Back to Contents Top of page Page 1 Page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

The first successful test firing of a Maggie Muggs type ramjet engine

was by Ben Koopman and teacher Randy Autrey at Gould Academy in

Maine, USA during the last week in April, 2005:

Ben looks on as his teacher Randy Autrey attempts to balance

the air input and fuel flow. It's easy to get too much fuel for the

airflow, as shown here. However, Randy claims that once you get

used to it, his 'squeeze bottle' method of delivering liquid fuel is

quite easy to use, since it gives you instant control over the fuel

pressure. From the mugs to the air source, Ben mostly used what they

found available at school, so his out-of-pocket cost for the project

was very low. One thing I recommended to Randy is that they try to

get a good leaf blower; that would provide a lot more air for cooling.

However, their initial tests were with what they had available, a

standard 'shop vac', and it seems to work well enough:

When more airflow and/or less fuel flow is applied, the flame starts

to look somewhat better - we're moving towards "lean" combustion:

When more airflow and/or less fuel flow is applied, the flame starts

to look somewhat better - we're moving towards "lean" combustion:

Continuing to lean out the burn. It looks like there's enough flame

and noise at this point that the test run is beginning to draw a

crowd. The mug parts were from teachers that were willing to donate

their used coffee mugs to the project, so these parts aren't exactly

like the ones shown in the plans; note, however, how Ben chose a mug

shell that has a well-developed combustion chamber zone and a good

long, smooth cone for the tail section - exactly the right approach!

Continuing to lean out the burn. It looks like there's enough flame

and noise at this point that the test run is beginning to draw a

crowd. The mug parts were from teachers that were willing to donate

their used coffee mugs to the project, so these parts aren't exactly

like the ones shown in the plans; note, however, how Ben chose a mug

shell that has a well-developed combustion chamber zone and a good

long, smooth cone for the tail section - exactly the right approach!

Leaning out the combustion even more makes the flame much less

visible, but significantly louder [note that the unlookers are starting

to back off a little!]. The sink strainer flameholder is one of the few

parts that had to be purchased new for the project; it keeps the

flame back in the tail section where we need it [unfortunately, the

flameholder can't be seen in any of these photos]:

Leaning out the combustion even more makes the flame much less

visible, but significantly louder [note that the unlookers are starting

to back off a little!]. The sink strainer flameholder is one of the few

parts that had to be purchased new for the project; it keeps the

flame back in the tail section where we need it [unfortunately, the

flameholder can't be seen in any of these photos]:

Once you get a really good lean run, the noise is a pretty intense

'jet noise' roar, and in daylight the visible flame almost disappears.

This is exactly the way your jet ought to be running. However, this is

also a very hot way to run, and the epoxy construction can't be

expected to take this for too long:

Once you get a really good lean run, the noise is a pretty intense

'jet noise' roar, and in daylight the visible flame almost disappears.

This is exactly the way your jet ought to be running. However, this is

also a very hot way to run, and the epoxy construction can't be

expected to take this for too long:

Finally, fuel pressure is cut back enough that flameout occurs,

before the glued construction suffers any damage. Ben keeps the

air flowing in for a while to cool things down:

Finally, fuel pressure is cut back enough that flameout occurs,

before the glued construction suffers any damage. Ben keeps the

air flowing in for a while to cool things down:

I first heard of this project via email back in mid-April, 2005, and briefly

corresponded with Randy Autrey a few times to offer encouragement and

minor suggestions. On May 1, I received the photos shown here, attached

to the following email from Randy summarizing successful construction and

testing of Ben's Maggie Muggs clone ramjet:

Larry,

You may use any or all of the following on jetZILLA or

wherever you would like.

My name is Randy Autrey and I work at Gould Academy,

a college preparatory boarding and day school in the

western mountains of Maine. I am a private pilot and I

also fly model airplanes. One of our students at

Gould, Ben K., saw the Maggie Muggs project on the

internet and asked if I could use it to fly one of my

model airplanes. I told him it looked like a fun

project and that we should build and test it. That is

exactly what we did.

We grabbed some freebie mugs from faculty members and

bought a sink strainer at Wal Mart. Ben used a dremel

tool to cut the mugs and we drilled a hole for the

brass tube injection system. We used JB weld to

assemble the mugs with the understanding that it was

only rated for 600 degrees F. Our first test fire was

with the small drilled brass tube which was flattened

in the center for a spray bar. We used a model

airplane fuel bottle to pressurize the gas mixture for

injection. The mug did ignite and produce a flame. It

was immediately obvious that we did not have enough

fuel. We went back to the lab to change the injection.

This time we just flattened the end of the brass

tubing and JB welded the tube to the front of the mug.

As you can see from the pictures we had plenty of

fuel. I like the pressurized bottle injection system

because you can control the flow. We started out with

light pressure during ignition and increased fuel

delivery as we increased shop vac air flow. You can

see this transition in the series of pictures of the

big flame 'blow torch' look during ignition to the

chiseled flame near the end. Just when the sound

changes and the flame becomes a chiseled point it is

time to shut down. This produces a lot of heat very

quickly when it hits efficiency.

This is a great project with very low cost and

construction effort. This was great for the students.

We are very pleased with the results. This Maggie Muggs

really draws a crowd.

We are planning on firing it again but this time we

will run it at night to see the transition from

ignition to chiseled flame. We hope to have a video

clip available soon. Stay tuned for more. We started

working on a valveless pulsejet so we will let you

know how that works out.

I would like to thank Larry for a fun design and all

of the emails he sent. Great job Larry.

Randy Autrey

Gould Academy

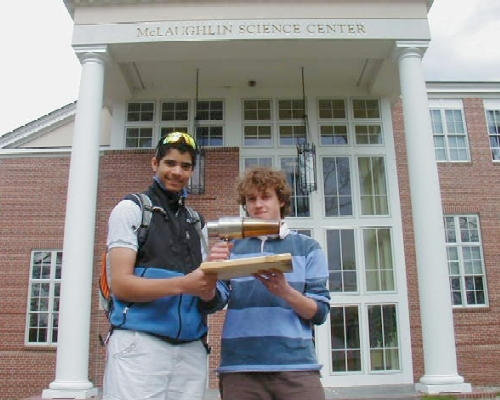

After test firing, Ben's Maggie Muggs clone is still in good

condition - Ben can take pride in building a finely-crafted,

nice-running engine!

I first heard of this project via email back in mid-April, 2005, and briefly

corresponded with Randy Autrey a few times to offer encouragement and

minor suggestions. On May 1, I received the photos shown here, attached

to the following email from Randy summarizing successful construction and

testing of Ben's Maggie Muggs clone ramjet:

Larry,

You may use any or all of the following on jetZILLA or

wherever you would like.

My name is Randy Autrey and I work at Gould Academy,

a college preparatory boarding and day school in the

western mountains of Maine. I am a private pilot and I

also fly model airplanes. One of our students at

Gould, Ben K., saw the Maggie Muggs project on the

internet and asked if I could use it to fly one of my

model airplanes. I told him it looked like a fun

project and that we should build and test it. That is

exactly what we did.

We grabbed some freebie mugs from faculty members and

bought a sink strainer at Wal Mart. Ben used a dremel

tool to cut the mugs and we drilled a hole for the

brass tube injection system. We used JB weld to

assemble the mugs with the understanding that it was

only rated for 600 degrees F. Our first test fire was

with the small drilled brass tube which was flattened

in the center for a spray bar. We used a model

airplane fuel bottle to pressurize the gas mixture for

injection. The mug did ignite and produce a flame. It

was immediately obvious that we did not have enough

fuel. We went back to the lab to change the injection.

This time we just flattened the end of the brass

tubing and JB welded the tube to the front of the mug.

As you can see from the pictures we had plenty of

fuel. I like the pressurized bottle injection system

because you can control the flow. We started out with

light pressure during ignition and increased fuel

delivery as we increased shop vac air flow. You can

see this transition in the series of pictures of the

big flame 'blow torch' look during ignition to the

chiseled flame near the end. Just when the sound

changes and the flame becomes a chiseled point it is

time to shut down. This produces a lot of heat very

quickly when it hits efficiency.

This is a great project with very low cost and

construction effort. This was great for the students.

We are very pleased with the results. This Maggie Muggs

really draws a crowd.

We are planning on firing it again but this time we

will run it at night to see the transition from

ignition to chiseled flame. We hope to have a video

clip available soon. Stay tuned for more. We started

working on a valveless pulsejet so we will let you

know how that works out.

I would like to thank Larry for a fun design and all

of the emails he sent. Great job Larry.

Randy Autrey

Gould Academy

After test firing, Ben's Maggie Muggs clone is still in good

condition - Ben can take pride in building a finely-crafted,

nice-running engine!

II. Maggie Muggs Testing Plan, Hints and Tips:

Previous section Back to Contents Top of page Page 1 Page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

MAGGIE MUGGS GENERAL TEST FIRING PLAN:

1. Secure engine to test bench, locking heat shield in place

2. Secure blower loosely to test bench

3. Align blower carefully on engine centerline, BOTH horizontally

and vertically while gradually tightening blower mounting

4. Make final check of blower alignment and spacing and secure

tight to test bench - be sure airflow covers entire engine

exterior!

5. Start spark ignition and verify good spark by visual sighting

from behind exhaust nozzle

6. Start blower and again verify good spark by sighting through nozzle

7. If possible, make preliminary thrust measurement - this is the

blower thrust minus total engine drag

8. Open fuel valve until combustion is achieved

9. Continue to open fuel valve until large, rich-burning flame

is observable - if this isn't obtainable, stop the test, your

fuel supply or valve is inadequate - otherwise, continue:

10. If possible, measure and record the rich-running thrust and

fuel flow

11. Reduce fuel flow to leaner running condition, pulling the flame

forward inside the nozzle - run for a few seconds and observe

the J-B Weld seam at the engine mid-point - if any signs of the

epoxy softening, shut off the fuel and allow time for the blower

to cool the engine - otherwise, continue:

12. Reduce fuel flow further, pulling the flame forward into the

aft region of the combustion chamber - if combustion is

observed inside the diffuser section, shut off the fuel and

allow time for the blower to cool the engine! - otherwise,

continue:

13. Shut off the spark ignition system - if the engine quits, shut

off the fuel and allow time for cooling! - otherwise, continue:

14. Try to obtain a running condition where only the nozzle zone is

visibly red hot, with no red heating of the combustion chamber -

if this is not obtainable, shut down and allow the blower to

cool the engine - otherwise, continue:

15. Run for several seconds and again observe the engine mid-point

seam - if there are signs of the epoxy softening, shut off the

fuel and allow time for the blower to cool the engine -

otherwise, continue:

16. If possible, measure and record the lean-running thrust and

fuel flow and the diffuser static pressure

17. Finish testing by quickly shutting off the fuel flow completely

18. Allow the blower to run until the entire engine structure is

cool enough to touch safely, then shut down blower

19. Adjust measured thrust figures by subtracting the unpowered

thrust value obtained in Step 7, above

MAGGIE MUGGS TESTING HINTS & TIPS:

Cooling air is just as important as combustion air!

1. Use the biggest air mover you can obtain. My choice was the

electrically powered Black & Decker Leaf Hog, capable of

120 MPH maximum air velocity, but any large-volume, high

velocity blower will work. A big shop vacuum is probably

just barely adequate for this application.

2. Position your air mover far enough from the engine intake so

that as much of the engine exterior as possible is constantly

bathed in high-speed airflow during and after a run. There

MUST be good airflow over the entire rear section of the

engine!

3. Make sure you have a 'quick cutoff' fuel valve that will let

you shut off fuel immediately if there is a failure of your

air mover. In fact, if you can figure out how to do it, it

wouldn't be a bad idea to route your fuel through an electric

valve with an air-driven switch for automatic shutdown in

case of air supply failure!

4. After a normal test run, make sure you keep your blower running

until the entire engine cools, to protect the J-B Weld bonds.

Even thin stainless holds heat a surprisingly long time and

heat flow from the tail cone forward after the run could

still lead to softening or degradation of the epoxy bead at

the engine mid-point if cooling is stopped too soon!

Start out running rich and work toward lean!

1. As soon as possible after you get ignition, try to get enough

fuel flowing to develop a rich-burning flame. This will keep

most of the combustion well to the rear, to minimize heat

buildup in the tail cone and, therefore, heat conduction to

the front end.

2. After you establish rich combustion, you can start leaning

the air/fuel mixture, gradually pulling the flame front

forward in the rear section of the engine, while regularly

testing the midsection J-B Weld bead for softness.

3. If the midsection epoxy bead starts to soften, you have

reached the limit of how lean you can set up the run with

the cooling you have available. At this point, it's time to

shut down the fuel [while letting the air cool down your

engine] until you can find a more effective air supply.

Start out with slow-burning fuel!

1. Start your testing with a slow-burning vapor fuel such as

propane or butane. That will make it easy to control the

position of the flame front in the engine by adjusting the

fuel flow.

2. If your air supply is so strong that you can't get the flame

front to move forward into the tail cone, reduce the entering

air velocity by putting more distance between the air nozzle

and the engine intake. Make sure you maintain good aiming of

the air nozzle so that you will have adequate cooling air

flow!

3. If you can achieve good engine operation, then you can try

more powerful, faster flame speed fuels such as MAPP gas.

You will probably want the highest possible entering air speed

for this to keep the flame front well in the rear of the

engine, and so throttling won't become over-sensitive.

4. It is strongly recommended that you provide a fuel pressure

regulator at the supply point, so you won't be fighting

pressure changes due to changing fuel temperature:

II. Maggie Muggs Testing Plan, Hints and Tips:

Previous section Back to Contents Top of page Page 1 Page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

MAGGIE MUGGS GENERAL TEST FIRING PLAN:

1. Secure engine to test bench, locking heat shield in place

2. Secure blower loosely to test bench

3. Align blower carefully on engine centerline, BOTH horizontally

and vertically while gradually tightening blower mounting

4. Make final check of blower alignment and spacing and secure

tight to test bench - be sure airflow covers entire engine

exterior!

5. Start spark ignition and verify good spark by visual sighting

from behind exhaust nozzle

6. Start blower and again verify good spark by sighting through nozzle

7. If possible, make preliminary thrust measurement - this is the

blower thrust minus total engine drag

8. Open fuel valve until combustion is achieved

9. Continue to open fuel valve until large, rich-burning flame

is observable - if this isn't obtainable, stop the test, your

fuel supply or valve is inadequate - otherwise, continue:

10. If possible, measure and record the rich-running thrust and

fuel flow

11. Reduce fuel flow to leaner running condition, pulling the flame

forward inside the nozzle - run for a few seconds and observe

the J-B Weld seam at the engine mid-point - if any signs of the

epoxy softening, shut off the fuel and allow time for the blower

to cool the engine - otherwise, continue:

12. Reduce fuel flow further, pulling the flame forward into the

aft region of the combustion chamber - if combustion is

observed inside the diffuser section, shut off the fuel and

allow time for the blower to cool the engine! - otherwise,

continue:

13. Shut off the spark ignition system - if the engine quits, shut

off the fuel and allow time for cooling! - otherwise, continue:

14. Try to obtain a running condition where only the nozzle zone is

visibly red hot, with no red heating of the combustion chamber -

if this is not obtainable, shut down and allow the blower to

cool the engine - otherwise, continue:

15. Run for several seconds and again observe the engine mid-point

seam - if there are signs of the epoxy softening, shut off the

fuel and allow time for the blower to cool the engine -

otherwise, continue:

16. If possible, measure and record the lean-running thrust and

fuel flow and the diffuser static pressure

17. Finish testing by quickly shutting off the fuel flow completely

18. Allow the blower to run until the entire engine structure is

cool enough to touch safely, then shut down blower

19. Adjust measured thrust figures by subtracting the unpowered

thrust value obtained in Step 7, above

MAGGIE MUGGS TESTING HINTS & TIPS:

Cooling air is just as important as combustion air!

1. Use the biggest air mover you can obtain. My choice was the

electrically powered Black & Decker Leaf Hog, capable of

120 MPH maximum air velocity, but any large-volume, high

velocity blower will work. A big shop vacuum is probably

just barely adequate for this application.

2. Position your air mover far enough from the engine intake so

that as much of the engine exterior as possible is constantly

bathed in high-speed airflow during and after a run. There

MUST be good airflow over the entire rear section of the

engine!

3. Make sure you have a 'quick cutoff' fuel valve that will let

you shut off fuel immediately if there is a failure of your

air mover. In fact, if you can figure out how to do it, it

wouldn't be a bad idea to route your fuel through an electric

valve with an air-driven switch for automatic shutdown in

case of air supply failure!

4. After a normal test run, make sure you keep your blower running

until the entire engine cools, to protect the J-B Weld bonds.

Even thin stainless holds heat a surprisingly long time and

heat flow from the tail cone forward after the run could

still lead to softening or degradation of the epoxy bead at

the engine mid-point if cooling is stopped too soon!

Start out running rich and work toward lean!

1. As soon as possible after you get ignition, try to get enough

fuel flowing to develop a rich-burning flame. This will keep

most of the combustion well to the rear, to minimize heat

buildup in the tail cone and, therefore, heat conduction to

the front end.

2. After you establish rich combustion, you can start leaning

the air/fuel mixture, gradually pulling the flame front

forward in the rear section of the engine, while regularly

testing the midsection J-B Weld bead for softness.

3. If the midsection epoxy bead starts to soften, you have

reached the limit of how lean you can set up the run with

the cooling you have available. At this point, it's time to

shut down the fuel [while letting the air cool down your

engine] until you can find a more effective air supply.

Start out with slow-burning fuel!

1. Start your testing with a slow-burning vapor fuel such as

propane or butane. That will make it easy to control the

position of the flame front in the engine by adjusting the

fuel flow.

2. If your air supply is so strong that you can't get the flame

front to move forward into the tail cone, reduce the entering

air velocity by putting more distance between the air nozzle

and the engine intake. Make sure you maintain good aiming of

the air nozzle so that you will have adequate cooling air

flow!

3. If you can achieve good engine operation, then you can try

more powerful, faster flame speed fuels such as MAPP gas.

You will probably want the highest possible entering air speed

for this to keep the flame front well in the rear of the

engine, and so throttling won't become over-sensitive.

4. It is strongly recommended that you provide a fuel pressure

regulator at the supply point, so you won't be fighting

pressure changes due to changing fuel temperature:

A good propane regulator and valve setup, built from an old-style Victor

high volume air regulator and needle valve. This has proved more than

ample for the fuel demands of my small pulsejet engine prototypes, and

should work fine for testing Maggie Muggs.

Photo Copyright 2004 Larry Cottrill

Test Firing 'Must Have' List:

1. Type A-B-C fire extinguisher

2. Hearing protection

3. Safety goggles

4. 'Quick shutoff' valve in fuel line

5. Largest volume blower you can find & reliable power

6. Outdoor or VERY well-ventilated 'fire safe' test site

7. Reliable fuel lines in good condition

8. Reliable ignition spark source

Test Firing 'Optional' List:

1. Thrust measurement stand for blower & engine

2. Water manometer for diffuser pressure measurement

3. Water manometer for velocity pressure measurement

4. Pressure regulator for fuel gas

Previous section Back to Contents Top of page Page 1 Page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

A good propane regulator and valve setup, built from an old-style Victor

high volume air regulator and needle valve. This has proved more than

ample for the fuel demands of my small pulsejet engine prototypes, and

should work fine for testing Maggie Muggs.

Photo Copyright 2004 Larry Cottrill

Test Firing 'Must Have' List:

1. Type A-B-C fire extinguisher

2. Hearing protection

3. Safety goggles

4. 'Quick shutoff' valve in fuel line

5. Largest volume blower you can find & reliable power

6. Outdoor or VERY well-ventilated 'fire safe' test site

7. Reliable fuel lines in good condition

8. Reliable ignition spark source

Test Firing 'Optional' List:

1. Thrust measurement stand for blower & engine

2. Water manometer for diffuser pressure measurement

3. Water manometer for velocity pressure measurement

4. Pressure regulator for fuel gas

Previous section Back to Contents Top of page Page 1 Page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

|