Photo Diary: How I Built the "Maggie Muggs" Low-Speed

Ramjet Prototype at home in my basement, using

ordinary hand tools and a handful of discount-store

materials, with NO WELDING, for under $60 US - PART I

by Larry Cottrill, Editor, jetZILLA Online Magazine

- All photos this page Copyright 2003 Larry Cottrill -

Table of Contents [Sections I-IV below]:

I. The parts lineup [28 August 2003]

II. The tubular truss engine mounts [28 August 2003]

III. Building the diffuser section [04 September 2003]

IV. Bonding the diffuser/flameholder subassembly to

the combustion chamber/nozzle shell [12 September 2003]

Table of Contents [Sections V-VIII go on to Page 2]

V. Final major assembly steps [22 September 2003]

VI. Details, details [22 September 2003]

VII. Fuel and ignition system work [29 September 2003]

VIII. Finishing up [03 October 2003]:

Table of Contents [Maggie Muggs Test Firing Page go on to Page 3]:

I. Ben Koopman's Maggie Muggs Clone [April 2005]

II. Maggie Muggs Testing Plan, Hints and Tips

I. The parts lineup [28 August 2003]:

Next section Back to Contents Top of page Page 2 Page 3

Subscribe to jetZILLA Online Magazine (it's FREE!)

II. The tubular truss engine mounts [28 August 2003]:

Previous section Next section Back to Contents Top of page Page 2 Page 3

Subscribe to jetZILLA Online Magazine (it's FREE!)

Gluing up an N-strut in my first gluing jig - the opposite strut,

semi-finished, and the fully cut rails are to the left. The rails

are .5 x .75 x 1/16 inch aluminum angle; the N-struts are cut

from the .25 OD titanium tubing contributed by my friend

Mark 'Thixis':

II. The tubular truss engine mounts [28 August 2003]:

Previous section Next section Back to Contents Top of page Page 2 Page 3

Subscribe to jetZILLA Online Magazine (it's FREE!)

Gluing up an N-strut in my first gluing jig - the opposite strut,

semi-finished, and the fully cut rails are to the left. The rails

are .5 x .75 x 1/16 inch aluminum angle; the N-struts are cut

from the .25 OD titanium tubing contributed by my friend

Mark 'Thixis':

The N-struts resting against a cardboard jig to align them

properly, with just enough J-B Weld to tack them to the rails:

The N-struts resting against a cardboard jig to align them

properly, with just enough J-B Weld to tack them to the rails:

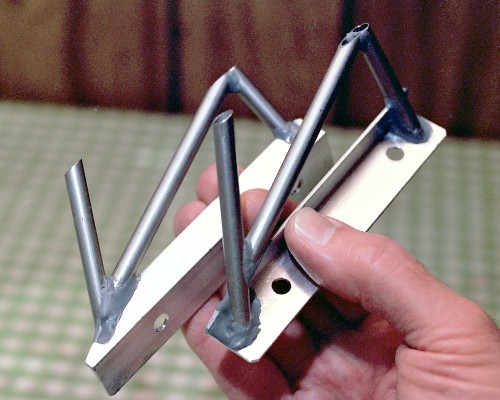

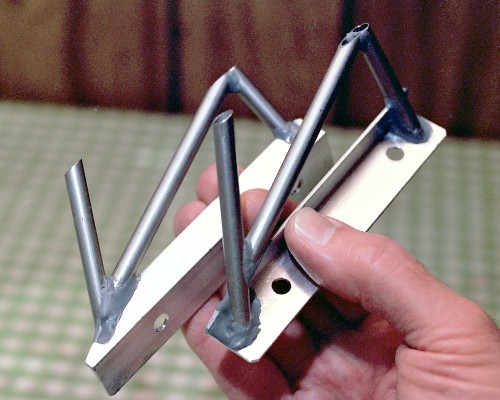

The finished engine mounts, fully reinforced with J-B Weld -

left mount in foreground, right mount behind:

The finished engine mounts, fully reinforced with J-B Weld -

left mount in foreground, right mount behind:

III. Building the diffuser section [04 September 2003]:

Previous section Next section Back to Contents Top of page Page 2 Page 3

Subscribe to jetZILLA Online Magazine (it's FREE!)

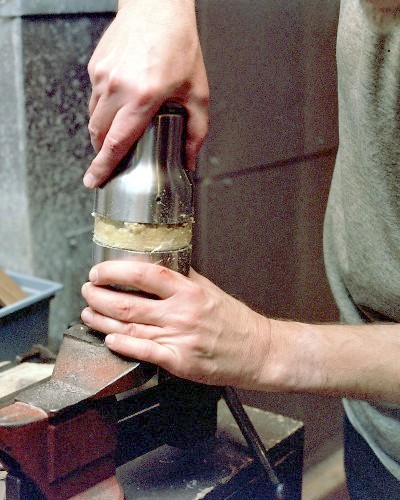

Here's a shot of cutting the groove around the mug shell. The mug

is rotated counterclockwise as seen from the top, with the saw

oriented as shown [for a left-handed blacksmith, set it all up

just the opposite way round]. I oiled the hacksaw blade, but

couldn't tell whether this really helped any - it was slow going:

III. Building the diffuser section [04 September 2003]:

Previous section Next section Back to Contents Top of page Page 2 Page 3

Subscribe to jetZILLA Online Magazine (it's FREE!)

Here's a shot of cutting the groove around the mug shell. The mug

is rotated counterclockwise as seen from the top, with the saw

oriented as shown [for a left-handed blacksmith, set it all up

just the opposite way round]. I oiled the hacksaw blade, but

couldn't tell whether this really helped any - it was slow going:

I tried starting the cut with the jeweler's saw, but found it

impossible to get a good starting cut, so I just ended up working

my way around it with the hacksaw until I knew I'd gotten fully

through it all around. The piece had to be moved in the vise jaws

four or five times:

I tried starting the cut with the jeweler's saw, but found it

impossible to get a good starting cut, so I just ended up working

my way around it with the hacksaw until I knew I'd gotten fully

through it all around. The piece had to be moved in the vise jaws

four or five times:

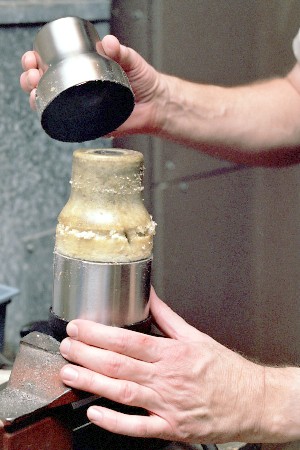

Oddly, the lower part of the shell was not that easy to remove,

because of the friction of the insulating foam tightly formed

inside:

Oddly, the lower part of the shell was not that easy to remove,

because of the friction of the insulating foam tightly formed

inside:

Finally, though, it does break free:

Finally, though, it does break free:

The edge requires a few minutes of work with a flat file and a

small half-round file to make it safe to handle:

The edge requires a few minutes of work with a flat file and a

small half-round file to make it safe to handle:

When I scraped off the non-skid ring attached to the end, I was

pleasantly surprised to find two little holes, so it was easy to

thread the jeweler's saw through to get a good start on the cut.

I just worked my way around, a bit inside the edge of the flat

end. Again, the piece had to be re-chucked in the vise a few

times; and, as predicted, I went through 6 or 7 saw blades to get

the whole end cut out. Unfortunately, neither the blade nor the

progressing saw kerf shows in the picture, since they are about

the width of a horse hair. It took about 45 minutes of sawing and

changing blades to complete the cut:

When I scraped off the non-skid ring attached to the end, I was

pleasantly surprised to find two little holes, so it was easy to

thread the jeweler's saw through to get a good start on the cut.

I just worked my way around, a bit inside the edge of the flat

end. Again, the piece had to be re-chucked in the vise a few

times; and, as predicted, I went through 6 or 7 saw blades to get

the whole end cut out. Unfortunately, neither the blade nor the

progressing saw kerf shows in the picture, since they are about

the width of a horse hair. It took about 45 minutes of sawing and

changing blades to complete the cut:

Even though the jeweler's saw is capable of accurate work, I

didn't try for real smoothness or precision. A fairly coarse

half-round file was perfect for evening up the hole - this only

took ten minutes or so:

Even though the jeweler's saw is capable of accurate work, I

didn't try for real smoothness or precision. A fairly coarse

half-round file was perfect for evening up the hole - this only

took ten minutes or so:

Then, a much smaller and finer half-round was used to smooth up

the opening for safe handling and inlet streamlining:

Then, a much smaller and finer half-round was used to smooth up

the opening for safe handling and inlet streamlining:

The finished diffuser behind the 'draggy flameholder'. All the

small parts of the sink basket strainer are removed and discarded.

Note the wonderful array of apertures in this high-quality

stainless strainer - a near-perfect 'burner grill':

The finished diffuser behind the 'draggy flameholder'. All the

small parts of the sink basket strainer are removed and discarded.

Note the wonderful array of apertures in this high-quality

stainless strainer - a near-perfect 'burner grill':

Both the inside edge of the diffuser [large end] and the entire

rolled rim of the flameholder have been roughened with sandpaper.

A small bead of J-B Weld has been applied to the INSIDE of the

diffuser rim. Here, I apply a HEAVY bead of J-B Weld over the

whole surface of the flameholder rim:

Both the inside edge of the diffuser [large end] and the entire

rolled rim of the flameholder have been roughened with sandpaper.

A small bead of J-B Weld has been applied to the INSIDE of the

diffuser rim. Here, I apply a HEAVY bead of J-B Weld over the

whole surface of the flameholder rim:

When the diffuser is inverted and lowered into place on this rim,

the two beads of cement will blend together to form a smooth,

strong 'glue fillet' that will lock the pieces together without

the chance of even the slightest gap, with just the slightest

bead of J-B Weld visible all around the outside.

IV. Bonding the diffuser/flameholder subassembly to

the combustion chamber/nozzle shell [12 September 2003]:

Previous section Next section Back to Contents Top of page Page 2 Page 3

Subscribe to jetZILLA Online Magazine (it's FREE!)

There is a significant gap [a couple of millimeters] between the

OD of the rear of the diffuser assembly and the ID of the front

edge of the combustor shell. A ring of solid J-B Weld is formed

around the diffuser rear edge to a depth of about 3/8 inch [about

8mm] to take up this difference. Believe it or not, the TOP

inside plastic rim of the Wal-Mart mug looked like just the right

dimensions to work as a mold for this epoxy ring. The trick is to

make sure the J-B Weld sticks to the stainless but not to the

plastic; so I smeared a thin coating of vegetable oil all over

the plastic rim internal surfaces. Then, a heavy coating of J-B

Weld was run around the rear diffuser where the flameholder is

bonded on, and this is then lowered, flameholder down, into the

top of the mug. J-B Weld is added by toothpick to finish filling

the gap, right up past the top of the plastic rim:

When the diffuser is inverted and lowered into place on this rim,

the two beads of cement will blend together to form a smooth,

strong 'glue fillet' that will lock the pieces together without

the chance of even the slightest gap, with just the slightest

bead of J-B Weld visible all around the outside.

IV. Bonding the diffuser/flameholder subassembly to

the combustion chamber/nozzle shell [12 September 2003]:

Previous section Next section Back to Contents Top of page Page 2 Page 3

Subscribe to jetZILLA Online Magazine (it's FREE!)

There is a significant gap [a couple of millimeters] between the

OD of the rear of the diffuser assembly and the ID of the front

edge of the combustor shell. A ring of solid J-B Weld is formed

around the diffuser rear edge to a depth of about 3/8 inch [about

8mm] to take up this difference. Believe it or not, the TOP

inside plastic rim of the Wal-Mart mug looked like just the right

dimensions to work as a mold for this epoxy ring. The trick is to

make sure the J-B Weld sticks to the stainless but not to the

plastic; so I smeared a thin coating of vegetable oil all over

the plastic rim internal surfaces. Then, a heavy coating of J-B

Weld was run around the rear diffuser where the flameholder is

bonded on, and this is then lowered, flameholder down, into the

top of the mug. J-B Weld is added by toothpick to finish filling

the gap, right up past the top of the plastic rim:

The fingertip is used to smooth out the top edge and remove the

slight excess. The thin film of J-B Weld left on the outside of

the diffuser shell is of no consequence:

The fingertip is used to smooth out the top edge and remove the

slight excess. The thin film of J-B Weld left on the outside of

the diffuser shell is of no consequence:

After allowing full curing time, the finished molded ring is

popped out of the mold by wiggling the diffuser [it comes out

easily] - note the inevitable small air voids; these will be

individually filled in with J-B Weld during the operation of

bonding to the combustor shell:

After allowing full curing time, the finished molded ring is

popped out of the mold by wiggling the diffuser [it comes out

easily] - note the inevitable small air voids; these will be

individually filled in with J-B Weld during the operation of

bonding to the combustor shell:

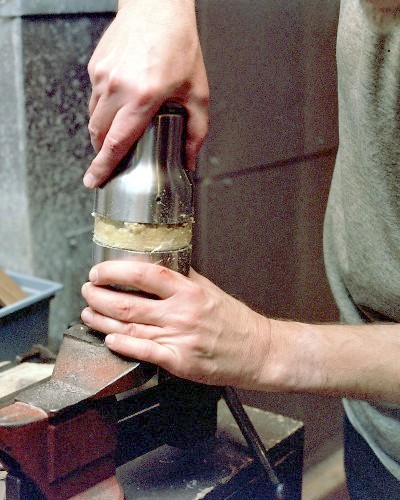

Now the Wal-Mart mug is disassembled, and the top rim of the

stainless shell is smoothed with a small file to remove slight

burrs. This is a trial fit of the epoxy ring into the edge of

the shell. Note the formed ridge of epoxy; the shell slides

easily over the main body of the ring, but balks at this ridge,

which will assure that the shell is perfectly aligned with the

diffuser assembly:

Now the Wal-Mart mug is disassembled, and the top rim of the

stainless shell is smoothed with a small file to remove slight

burrs. This is a trial fit of the epoxy ring into the edge of

the shell. Note the formed ridge of epoxy; the shell slides

easily over the main body of the ring, but balks at this ridge,

which will assure that the shell is perfectly aligned with the

diffuser assembly:

The epoxy ring must be cleaned thoroughly with strong alcohol to

make sure there is no residue of the cooking oil.

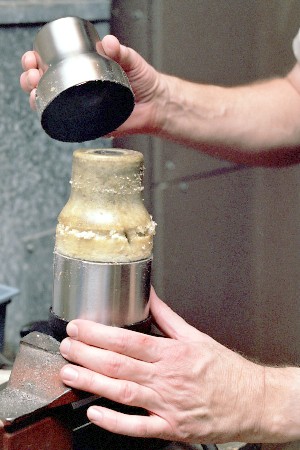

Using medium sandpaper to roughen the inside edge of the shell to

ensure solid bonding [this area is also de-greased with strong

alcohol]:

The epoxy ring must be cleaned thoroughly with strong alcohol to

make sure there is no residue of the cooking oil.

Using medium sandpaper to roughen the inside edge of the shell to

ensure solid bonding [this area is also de-greased with strong

alcohol]:

Finally, the entire outer surface of the epoxy ring is coated with

J-B Weld and the little voids are all filled in. Then, a HEAVY

bead of J-B Weld is applied all around the INSIDE of the front

edge of the shell. The diffuser assembly is inverted and the shell

is lowered into place around it, until it comes to rest on the

molded ridge. This is the orientation it is left in until the bond

is fully cured. Here, I wipe excess epoxy off the outside with a

dry paper towel; the residual film will be removed by a little

fine sanding:

Finally, the entire outer surface of the epoxy ring is coated with

J-B Weld and the little voids are all filled in. Then, a HEAVY

bead of J-B Weld is applied all around the INSIDE of the front

edge of the shell. The diffuser assembly is inverted and the shell

is lowered into place around it, until it comes to rest on the

molded ridge. This is the orientation it is left in until the bond

is fully cured. Here, I wipe excess epoxy off the outside with a

dry paper towel; the residual film will be removed by a little

fine sanding:

Previous section Next section Back to Contents Top of page Page 2 Page 3

Subscribe to jetZILLA Online Magazine (it's FREE!)

Previous section Next section Back to Contents Top of page Page 2 Page 3

Subscribe to jetZILLA Online Magazine (it's FREE!)

All film processing and negative

scanning for this page was done by

Multi Media Imaging

1526 Walnut Street

Des Moines, Iowa USA 50309

515-309-3456

www.multi-media-inc.com

All film processing and negative

scanning for this page was done by

Multi Media Imaging

1526 Walnut Street

Des Moines, Iowa USA 50309

515-309-3456

www.multi-media-inc.com

|

|