| Jet engines |

|

YOU could save

a child's life! >>> |

|

|

| You have arrived at the Original

|

| SYNCHRODYNE jet engine TESTING page! |

|

The

SYNCHRODYNETM

project - November-December 2001

(last content update: 15 Dec 2001) |

SYNCHRODYNETM

engine Experimental Test Journal:

- Physical setup (typical for all tests):

- Mounting: engine bolted to test mount, test mount clamped in metal vise,

vise resting on concrete floor

- Fuel system: 1-1/2 ounce metal fuel tank (not pressurized), with clear vinyl

fuel hose (protected with wadded aluminum foil all around), dual ported

fuel delivery tube with Norvell needle valve assembly

- Air system: steel pressure tank with adjustable regulator, intermittent-duty

('push button') valve and rubber hose with standard 'tire' fitting

- Ignition system: Model T Ford spark coil driven with 12V alkaline battery,

intermittent-duty ('push-button') switch, high-tension leads with clips,

Champion V-3 miniature spark plug

SynchrodyneTM Version 1.0 -

- 12/01/2001 - Test Session 1 -

- Test plan:

- Achieve continuos operation, try to determine basic operating settings

- Starting conditions:

- Atmospheric conditions: cool (~ 45 degF), dry

- Lighting conditions: daylight (cloudy bright)

- Starting air: 10 PSI

- Needle valve setting: 3 turns open

- Fuel used: ethyl ether

- Video recording setup: extreme closeup of intake area

- Procedures and observations:

- No ignition at 10 PSI air pressure

- Increased to 15 PSI - no ignition observed

- Increased to 20 PSI - still no ignition observed

- At 20 PSI, tried short bursts of air - no ignition observed

- Back to 10 PSI, closed needle valve to 2 turns - no ignition observed

- Increased to 18 PSI - no ignition except dull pops at start of spark

- Increased to 25 PSI - no ignition observed

- Increased to 30 PSI - no ignition observed

- Opened needle valve to 4 turns - fairly loud pop, nothing more

- Reduced air back to 10 PSI - IMMEDIATELY GOT STEADY COMBUSTION! After a

couple of seconds, runs without spark (shuts down without forced air, however).

Flame seems too bright and running is somewhat noisy and a little rough (must be

too fuel rich). There is no pulsing, and no observable flame ejection from the

intake port. Some white smoke from the port, however, between burns.

- Reduced needle valve to 3 turns - no firing

- Increased to 3-1/2 turns - brief, intermittent multiple firings

- Increased to 4 turns - constant burn, even without spark, but soon quit

- Reduced to 3-1/2 turns while running - good loud combustion, but rough and

somewhat intermittent

- Noticed starting air pressure low - this may have caused the roughness observed in the

last few tries

- Re-filled air tank

- 12/01/2001 - Test Session 2 -

- Test plan:

- Try to achieve pulse operation and determine basic operating settings

- Starting conditions:

- Atmospheric conditions: cool (~ 45 degF), dry

- Lighting conditions: daylight (cloudy)

- Starting air: 22 PSI

- Needle valve setting: 4-1/2 turns open

- Fuel used: ethyl ether

- Video recording setup: extreme closeup of intake area

- Procedures and observations:

- Slight firing, popping

- Increased to 30 PSI - no firing

- Removed spark plug, checked spark -- OK! Replaced plug

- Back to 10 PSI - still no ignition observed

- Re-filled fuel tank

- Increased to 15 PSI - erratic short bursts of combustion

- Reduced to 10 PSI - good, constant combustion!

- Combustion 'breaks up' after a couple of minutes

- Increased needle valve to 5-1/2 turns - rough, intermittent, with loud banging

- Reduced needle valve to 5 turns, set 15 PSI - no firing

- Reduced to 4-1/2 turns - no firing

- Camera technician notices absence of fuel spray into port!

- Re-filled fuel tank

- Re-filled air tank

- Removed foil shield from fuel line so flow can be observed

- 12/01/2001 - Test Session 3 -

- Test plan:

- Try to achieve steadier continuous combustion, less roughness

- Starting conditions:

- Atmospheric conditions: cool (~ 42 degF), dry

- Lighting conditions: dusk

- Starting air: 15 PSI

- Needle valve setting: 4-1/2 turns open

- Fuel used: ethyl ether

- Video recording setup: wide angle so exhaust flame is observable

- Procedures and observations:

- Intermittent firing

- Increased needle valve to 5 turns - some intermittent firing, then nothing!

- Observed a lot of air in the fuel line - rearranged so that fuel feed pipe is

nearer fuel tank low point

- Still only intermittent firing - very poor fuel flow observed

- Re-filled fuel tank

- Still at 15 PSI, 5 turns - intermittent firing, exhaust flame 'blowing out'

(separating from tailpipe end)

- Reduced to 10 PSI - good, constant combustion as long as air supplied!

- Now that we have good fuel flow, foil shield is replaced for safety

- Long run at 5 turns & 10 PSI - begins alternate 'fading' and 'surging' combustion!

- Observed not much air left

- One last try at 20 PSI - nothing! Again, no fuel spray visible

- Re-filled fuel tank

- Re-filled air tank

- 12/01/2001 - Test Session 4 -

- Test plan:

- Again, try to achieve steadier continuous combustion

- Starting conditions:

- Atmospheric conditions: cool (~ 40 degF), dry

- Lighting conditions: late dusk; almost dark

- Starting air: 12 PSI

- Needle valve setting: 4-1/2 turns open

- Fuel used: ethyl ether

- Video recording setup: wide angle so exhaust flame is observable

- Procedures and observations:

- Tried once again to adjust fuel feed pipe as low as possible

- At 12 PSI, good start, constant burn, good staeady flame & noise

- Gradually lowered air pressure - still no pulse running, much reduced flame

and noise

- Above 12 PSI, unsteady or intermittent combustion, flame 'blowout'

- Tried leaner setting (less than 4 turns open) - unsteady combustion

- At 4 turns open, good steady combustion, but won't run long without

spark

- Experimental conclusions (tentative):

- 10 PSI air pressure is about right for starting

- Needle valve 3-1/2 to 4 turns open is a good starting point for starting & running

- Higher air pressures seem to be of no benefit

- Lower air pressures don't create adequate fuel uptake

- No observed gas flow forward into the velocity duct

- No observed pulsejet operation - more like forced-air burner action

- Internal conditions aren't right for pulse operation - insufficient 'back pressure'

to cause valving, maybe, or combustion too far downstream in the pipe due to excessive

starting air velocity through the combustion zone, even when combustion is

'holding' in the pipe

- Synopsis of test results:

- No pulsejet action observed

- Combustion seems to be well downstream in the pipe, with little flow

acceleration

- At this point, would be a good laboratory burner, not much of an engine

- Proposed modifications prior to further testing:

- Modification: Form a fairly restrictive exit nozzle at the rear of the tailpipe in lieu

of the 'straight pipe' design.

- Theory: Exhaust nozzle will increase static pressure in the tube (including within the

combustion zone), retard fluid flow downstream in the tailpipe for better

combustion, and more nearly 'balance' flow resistance between the front and rear

ends of the main tube, so that forward flow through the velocity duct will be

encouraged.

- Designation: Because of the crucial nature of the nozzle addition, this modification

will be designated Version 2.0

SynchrodyneTM Version 2.0 -

- 12/05/2001 - Test Session 5 -

- Test plan:

- Determine basic operating settings with exhaust nozzle

- Starting conditions:

- Atmospheric conditions: cool (~ 45 degF), humid (rainy earlier)

- Lighting conditions: daylight (cloudy)

- Starting air: 10 PSI

- Needle valve setting: 3 turns open

- Fuel used: ethyl ether

- Video recording setup: extreme closeup of intake area

- Procedures and observations:

- No ignition - observed fairly large bubbles in fuel line

- Increased needle valve to 3-1/2 turns open - no ignition observed,

except occasional pops at start of spark

- Increased to 4 turns open - slight backfiring at start of airflow

- Steady combustion (no sign of pulse operation), quits after a few seconds

without spark

- Reduced to 3-1/2 turns - slight pops, then solid burn but again quits after a

while; some smoke from the intake port between burns

- Reduced to 3 turns open - erratic firing, obviously too lean mixture

- Increased to 4 turns open - steady combustion

- Gradually reduced air pressure - significant reduction in flame and noise,

eventually some roughness, eventually combustion leaving the pipe and

taking place entirely outside the exhaust nozzle!

- Combustion roughening, then breaking up - poor air pressure due to tank

running out of air

- Re-filled fuel tank

- Re-filled air tank

- 12/05/2001 - Test Session 6 -

- Test plan:

- Starting air initially at 10 PSI, test operation at gradually higher pressures

- Starting conditions:

- Atmospheric conditions: cool (~ 45 degF), humid

- Lighting conditions: daylight (cloudy)

- Starting air: 10 PSI

- Needle valve setting: 4 turns open

- Fuel used: ethyl ether

- Video recording setup: wide angle view

- Procedures and observations:

- Rough and intermittent burning

- Increased to 4-1/2 turns open - some backfiring, combustion a little rough

- Reduced back to 4 turns - still somewhat rough running

- Reduced to 3-1/2 turns - no firing!

- Increased to 12 PSI and 4-1/2 turns - solid combustion, then breaks up

- Increased to 5 turns open - loud, very intermittent!

- Reduced to 4 turns open, but up to 14 PSI - erratic firing

- Reduced pressure to 10 PSI - out of tape in the camcorder!

- Erratic firing - probably a fuel delivery problem

- Experimental conclusions (tentative):

- Exactly the same as Version 1.0, except for some slight backfiring observed and

generally less stable combustion

- Synopsis of test results:

- Some backfiring observed, but still no identifiable pulsejet action

- Combustion seems to be well downstream in the pipe, sometimes taking place completely

behind the exhaust nozzle; little flow acceleration in the tailpipe

- Still behaving like a liquid-fueled burner, not a thrust engine

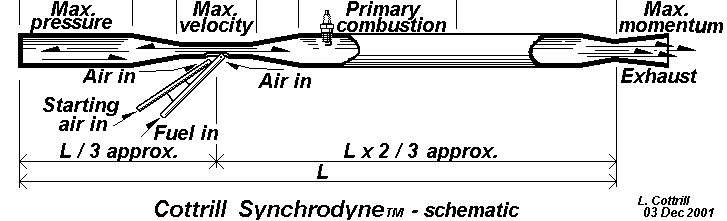

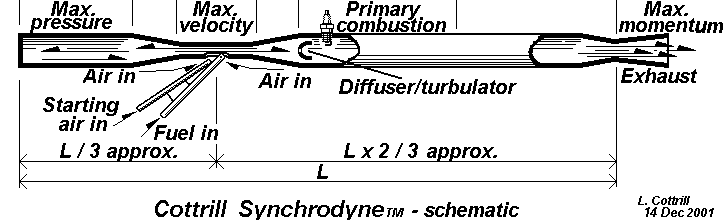

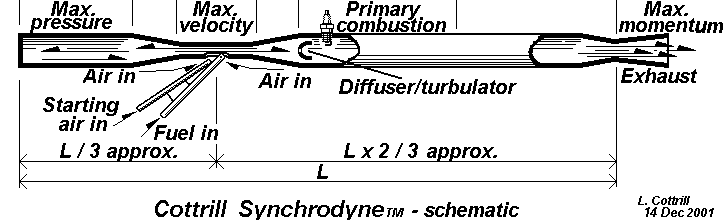

- Proposed modifications prior to further testing:

- Modification: Form a fairly draggy diffuser/turbulator at the front of the primary

combustion zone.

- Theory: Diffuser/turbulator will retard the overdriven starting air/fuel mixture as it

enters the combustion zone, allowing time for explosive mixture to stabilize. Also,

turbulence imposed on the incoming stream will aid fuel vaporization for more rapid

ignition near the front of the combustion zone.

- Designation: This modification will be designated Version 2.1 - changes to the exact

design of the diffuser/turbulator will take subsequent decimal divisions (2.2, 2.3, etc.)

SynchrodyneTM Version 2.1 -

| The

SYNCHRODYNETM

miniature jet engine |

Now under development by

Corporate Main Office

11905 NE 110th Ave

Mingo, IA 50168-9500

Contact: synchrodyne@cottrillcyclodyne.com

Page updated: 28 August 2002

Copyright 2001 Cottrill Cyclodyne Corporation

- All rights reserved -